A Practical Buyer’s Guide for Food, Beverage & Pharmaceutical Industries

Introduction: Why IP69K Matters in Real Washdown Environments

In hygienic industries such as food processing, beverage production, and pharmaceuticals, daily high-pressure washdown is not optional — it is a regulatory requirement.

However, many industrial panel PCs labeled as “waterproof” fail prematurely due to corrosion, water ingress, or poor hygienic design.

This guide explains how to choose a truly reliable IP69K panel PC, based on real-world washdown conditions — not just IP ratings on paper.

What Is an IP69K Panel PC?

An IP69K panel PC is designed to withstand:

- High-pressure water jets (up to 80–100 bar)

- High-temperature washdown (up to 80 °C)

- Close-range, multi-angle spray cleaning

- Repeated exposure to aggressive detergents and disinfectants

Unlike IP65 or IP67 devices, IP69K systems are engineered for frequent, long-term washdown cycles, commonly found in hygienic production zones.

Important: A panel PC is only IP69K if the entire system, including I/O and cable exits, meets the same protection level.

Key Factors When Choosing an IP69K Panel PC

Stainless Steel Enclosure: SUS304 vs SUS316

The enclosure material is one of the most critical design decisions.

Recommended materials:

- SUS304 stainless steel – suitable for most food and beverage applications

- SUS316 stainless steel – preferred for pharmaceutical, dairy, high-salt, or chemically aggressive environments

Why stainless steel is essential:

- Superior corrosion resistance

- No paint peeling or surface degradation

- Easy to clean and disinfect

- Complies with hygienic design principles

Painted aluminum or coated steel enclosures may appear cost-effective, but they rarely survive long-term washdown use.

Hygienic Design Is More Than Waterproofing

A true washdown panel PC must be hygienically designed, not merely sealed.

Look for:

- Seamless front bezel

- Rounded edges without dirt traps

- No exposed front screws

- Smooth, easy-to-clean surfaces

These features reduce bacterial buildup and help facilities pass hygiene audits more easily.

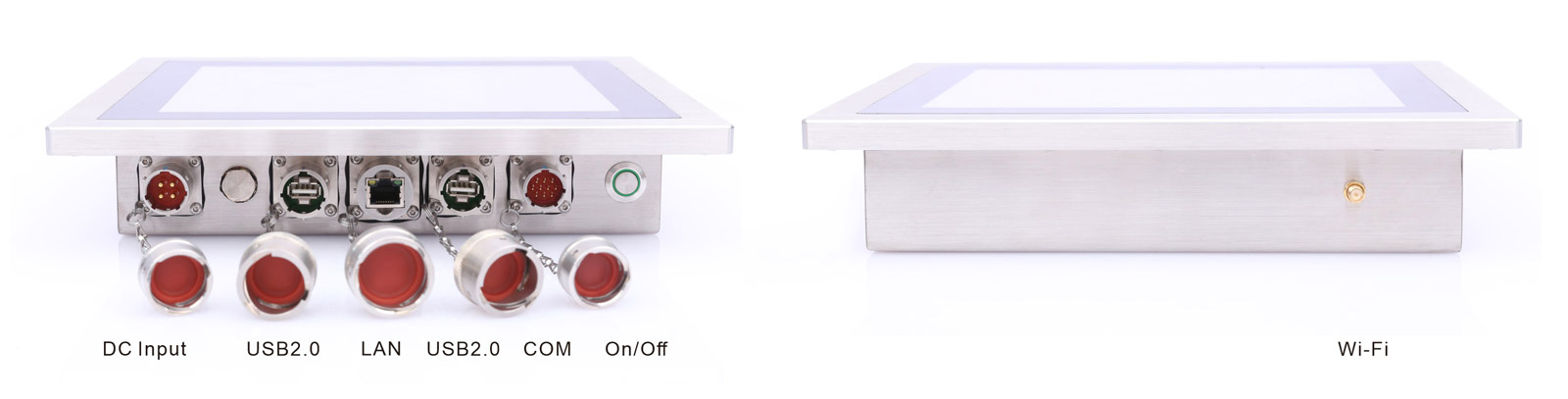

IP69K-Rated I/O and Cable Management

In washdown environments, connectors are the most common failure point.

A reliable IP69K panel PC should include:

- Fully sealed I/O protection

- Waterproof connectors (such as M12 or sealed aviation connectors)

- Downward-facing cable exits to prevent water accumulation

- No exposed rubber gaskets

If the front panel is IP69K but the connectors are only IP65, the system is not truly IP69K.

Touch Screen Performance Under Wet Conditions

Touch functionality must remain reliable during cleaning and operation.

Recommended features:

- Projected capacitive (PCAP) touch with water-rejection technology

- Optional glove-touch support

- Chemically strengthened or tempered glass

While resistive touch is still used in some cases, modern hygienic facilities increasingly prefer PCAP touch for durability and user experience.

Performance Considerations for Industrial Operation

Fanless Industrial-Grade CPUs

Common processor options include:

- Intel® Celeron® (e.g., J6412, N5100)

- Intel® Core™ i3 / i5 (12th or 13th generation)

Why fanless design matters:

- No air intake, no contamination risk

- Lower mechanical failure rate

- Quiet and maintenance-free operation

Storage and Memory Reliability

For continuous industrial use, choose:

- Industrial-grade SSDs

- Wide-temperature memory modules

- Shock and vibration-resistant components

These factors are essential for 24/7 production lines where downtime is costly.

Mounting Options for Washdown Applications

Different production environments require different mounting solutions:

- VESA mount – flexible and widely compatible

- Yoke or swing-arm mount – ideal for washdown HMIs

- Panel mount – integrated into machinery with sealed installation

Mounting design must preserve full IP69K protection after installation.

Typical Applications of IP69K Panel PCs

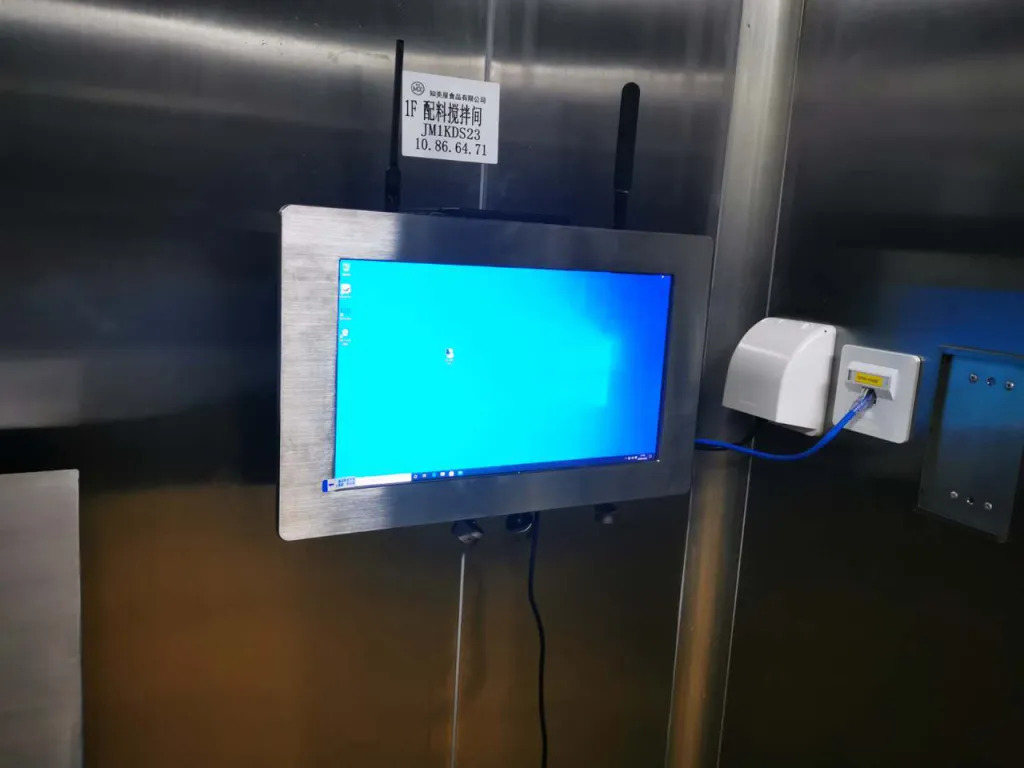

- Food and beverage processing lines

- Meat, poultry, and seafood facilities

- Dairy production and filling systems

- Pharmaceutical cleanrooms

- Chemical washdown areas

If your equipment is exposed to daily high-pressure cleaning, IP69K is a necessity — not an upgrade.

Why Purpose-Built IP69K Panel PCs Last Longer

Some industrial computers are simply adapted for washdown environments.Purpose-built IP69K panel PCs are designed from the start for hygienic operation.

This results in:

- Longer service life

- Lower maintenance costs

- Higher system uptime

- Easier compliance with hygiene standards

Final Buyer Checklist

Before purchasing, confirm that the panel PC offers:

✔ Stainless steel enclosure (304 or 316)

✔ True IP69K protection for the entire system

✔ Hygienic, easy-to-clean design

✔ Fanless industrial-grade CPU

✔ Washdown-ready touch technology

Meeting all five criteria ensures a reliable long-term washdown solution.

Looking for a Purpose-Built IP69K Panel PC?

At washdownpc.com, we focus exclusively on stainless steel IP69K panel PCs designed for real washdown environments in food, beverage, and pharmaceutical industries.

Explore solutions engineered for hygiene, durability, and long-term reliability.