In food processing facilities, washdown cleaning is part of the production process, not a maintenance exception.

Industrial PCs installed on processing or packaging lines must therefore be designed to withstand frequent high-pressure, high-temperature cleaning while maintaining hygienic integrity.

In many food plants, IP69K is not a preference but a requirement.

This article explains:

- Why IP69K is often mandatory in food processing washdown areas

- What technical and mechanical requirements IP69K industrial PCs must meet

- Common non-compliance issues seen in real food production environments

Why IP69K Is Often Mandatory in Food Processing Facilities

Food processing washdown areas combine several demanding conditions:

High-Pressure, High-Temperature Cleaning

Typical cleaning procedures involve:

- High-pressure water jets (often 80–100 bar)

- Hot water cleaning (up to 80 °C)

- Foam and chemical detergents

- Close-range, multi-angle spraying

Industrial PCs not designed for these conditions frequently suffer from seal failure, water ingress, or corrosion.

Strict Hygiene and Audit Requirements

Food safety regulations require:

- Thorough and repeatable cleaning

- No hidden contamination points

- Equipment surfaces that can be visually inspected

IP69K-rated industrial PCs support these requirements by ensuring full enclosure integrity during cleaning.

What IP69K Means in Practical Engineering Terms

IP69K certification verifies resistance to:

- High-pressure water jets

- High-temperature washdown

- Close-distance spraying from multiple angles

- Repeated washdown cycles

Unlike IP67, which focuses on temporary immersion, IP69K directly addresses real washdown cleaning processes used in food plants.

Core IP69K Requirements for Industrial PCs in Food Processing

Stainless Steel Enclosure (Hygienic Material Selection)

Industrial PCs in food washdown areas should use:

- SUS304 stainless steel for general food processing

- SUS316 stainless steel for dairy, meat, seafood, or high-salt environments

Key reasons include:

- High corrosion resistance

- No coating or paint degradation

- Smooth, cleanable surfaces

- Long-term hygienic stability

Hygienic Mechanical Design (Beyond Waterproofing)

IP69K compliance requires more than sealing.

A compliant industrial PC should feature:

- Seamless front surfaces

- Rounded edges and sloped geometries

- No exposed front screws or recesses

- Fully sealed seams

These design features reduce bacterial buildup and simplify sanitation procedures.

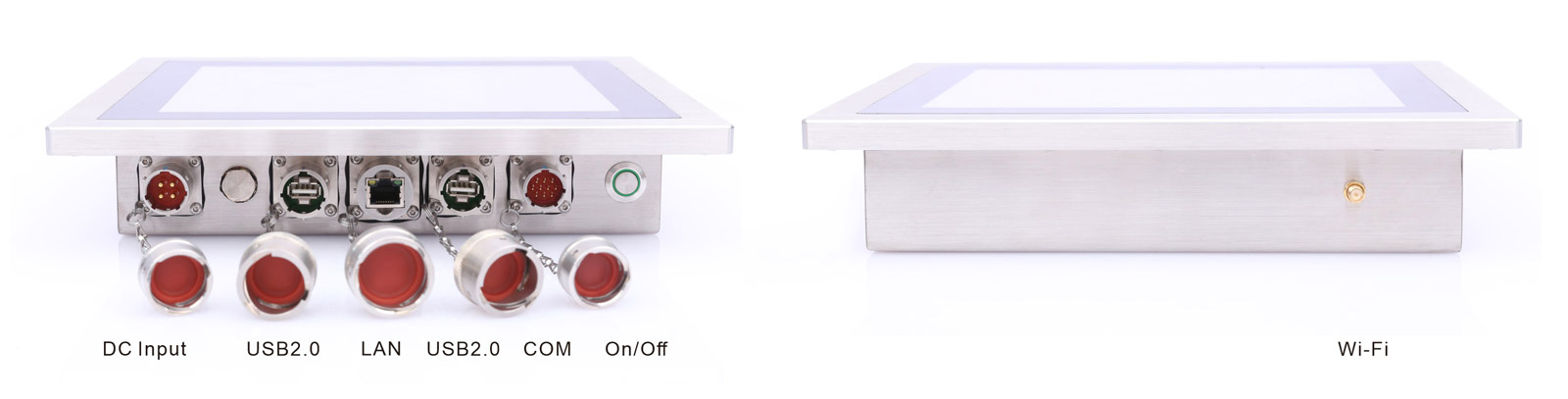

IP69K-Rated I/O and Cable Interfaces

In washdown environments, connectors are often the weakest point.

IP69K industrial PCs should include:

- Fully sealed I/O protection

- Washdown-rated connectors (e.g., M12 or sealed industrial connectors)

- Downward-facing cable exits to prevent water pooling

Front-panel IP69K protection is insufficient if I/O areas do not meet the same standard.

Seal Design and Long-Term Durability

IP69K-rated systems require:

- Pressure-resistant sealing materials

- Gaskets designed for thermal cycling

- Resistance to chemical detergents

Seals designed only for static immersion (IP67) typically degrade under repeated pressure and heat.

Fanless Industrial Architecture

Fanless design is strongly preferred in food processing environments because:

- No air intake reduces contamination risk

- Fewer moving parts improve reliability

- Cleaning procedures are simplified

Fanless IP69K industrial PCs align well with hygienic production requirements.

Common IP69K Non-Compliance Issues in Food Plants

From field experience, the most frequent issues include:

- IP69K front panel combined with IP65 connectors

- Painted or coated enclosures marketed as “washdown”

- Flat surfaces with sharp internal corners

- Cable glands not rated for high-pressure washdown

These issues often result in audit failures, corrosion, or unplanned downtime.

Engineering Checklist for IP69K Industrial PCs in Food Processing

Before approval or installation, confirm that the system offers:

✔ Stainless steel enclosure (304 or 316)

✔ Full system IP69K protection (including I/O)

✔ Hygienic, easy-to-clean mechanical design

✔ Washdown-resistant sealing materials

✔ Fanless industrial architecture

Meeting all criteria ensures long-term reliability and hygiene compliance.

Why Purpose-Built IP69K Industrial PCs Are Preferred

Industrial PCs adapted from standard designs often meet IP ratings in laboratory tests but fail under real washdown conditions.

Purpose-built IP69K systems are:

- Designed specifically for food processing washdown

- Tested under realistic cleaning conditions

- More reliable over long service life

This reduces maintenance, downtime, and total cost of ownership.

IP69K Industrial PCs for Food Processing Washdown Applications

At washdownpc.com, we focus on stainless steel IP69K industrial PCs engineered for food processing washdown environments.

Our systems are designed to meet:

- Hygienic design principles

- True system-level IP69K protection

- Long-term reliability in daily washdown operations

For food processing facilities where cleaning is part of normal operation, IP69K is not an option—it is the correct engineering requirement.