In food processing facilities, daily cleaning and sanitation are mandatory, not optional.

Production lines are routinely washed down using high-pressure water, foam, and chemical detergents to meet food safety and hygiene regulations.

Standard industrial PCs are not designed for this type of environment.

This is why washdown-ready industrial PCs are essential for modern food processing plants.

This article explains:

- Why food processing environments are especially demanding

- What requirements an industrial PC must meet for washdown use

- Which design features matter most in hygienic production lines

Why Food Processing Washdown Environments Are Challenging

Food production combines three critical stress factors:

Frequent High-Pressure Cleaning

Equipment is often cleaned:

- Daily or multiple times per shift

- With high-pressure water jets

- Using hot water and alkaline or acidic detergents

These conditions place continuous stress on seals, connectors, and enclosures.

Strict Hygiene and Food Safety Requirements

Food processing environments must prevent:

- Bacterial growth

- Cross-contamination

- Accumulation of residues

Any industrial PC installed on the production line must support easy, thorough cleaning.

Corrosive Conditions

Moisture, cleaning chemicals, and food residues create a highly corrosive environment.

Materials and surface finishes that work in dry factories often fail quickly in food plants.

Why Standard Industrial PCs Fail in Food Processing Areas

Standard industrial PCs are typically designed for:

- Dust

- Vibration

- Temperature variation

They are not designed for direct exposure to water and cleaning chemicals.

Common failure modes include:

- Water ingress through connectors or seams

- Corrosion of enclosures and fasteners

- Seal degradation due to repeated pressure and heat

- Increased downtime and maintenance costs

In food processing plants, these failures can quickly become food safety risks.

Key Requirements for Industrial PCs in Food Processing Washdown Areas

Stainless Steel Enclosure (304 or 316)

Stainless steel is the preferred material for hygienic environments.

- SUS304: Suitable for most food processing applications

- SUS316: Recommended for dairy, meat, seafood, or high-salt environments

Benefits include:

- Excellent corrosion resistance

- No paint or coating to peel

- Smooth, easy-to-clean surfaces

- Compliance with hygienic design principles

High Ingress Protection for Washdown

For food processing washdown zones, the protection level must match the cleaning process:

- IP66: Protection against strong water jets

- IP67: Protection against temporary immersion

- IP69K: Protection against high-pressure, high-temperature washdown

For daily high-pressure cleaning, IP69K is generally required.

Hygienic Mechanical Design

A washdown-ready industrial PC should feature:

- Seamless front surfaces

- Rounded edges without dirt traps

- No exposed screws on the front panel

- Fully sealed seams

These features reduce contamination risks and simplify sanitation procedures.

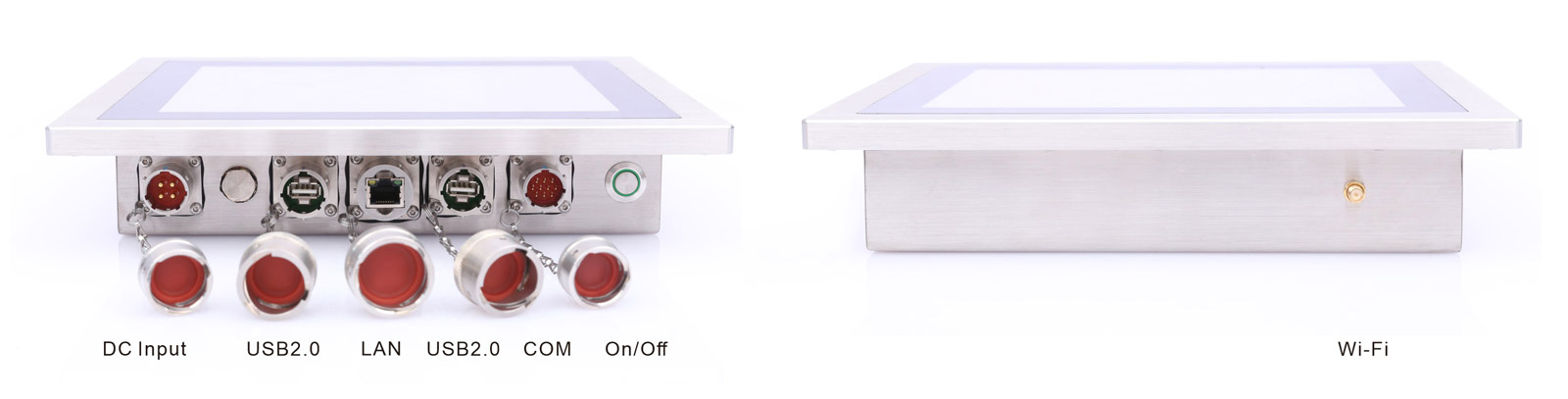

Washdown-Rated I/O and Cable Management

Connectors are one of the most vulnerable points in wet environments.

Recommended design features include:

- Sealed I/O covers

- Waterproof connectors (e.g., M12 or sealed aviation connectors)

- Downward-facing cable exits to prevent water pooling

Without proper I/O protection, even a waterproof enclosure can fail.

Fanless Industrial Architecture

Food processing plants benefit from fanless industrial PCs because:

- No air intake means no contamination risk

- Fewer moving parts reduce failure rates

- Maintenance requirements are lower

Fanless designs are especially important in hygienic environments.

Typical Applications in Food Processing Plants

Washdown-ready industrial PCs are commonly used for:

- HMI control on processing and packaging lines

- Production monitoring and data collection

- Quality control and inspection systems

- Recipe management and batch tracking

They are often installed directly on machines or close to processing equipment, where washdown exposure is unavoidable.

Engineering Recommendation for Food Processing Facilities

From an engineering perspective, industrial PCs used in food processing washdown areas must be:

- Designed specifically for wet, hygienic environments

- Constructed from corrosion-resistant materials

- Rated for the actual cleaning process used on site

Selecting a PC based only on “waterproof” claims often leads to premature failure and higher total cost of ownership.

Choosing the Right Industrial PC for Food Processing Washdown

Before selecting an industrial PC, food processing facilities should evaluate:

- Cleaning pressure, temperature, and chemicals

- Required hygiene standards

- Installation location and mounting method

- Performance and reliability requirements

Matching the PC design to real-world washdown conditions is essential for long-term reliability.

Purpose-Built Industrial PCs for Food Processing Washdown

At washdownpc.com, we focus on stainless steel industrial PCs designed specifically for food processing washdown environments.

Our systems are engineered with:

- SUS304 / SUS316 stainless steel enclosures

- True IP69K protection, including I/O

- Hygienic, easy-to-clean mechanical design

- Fanless industrial architecture

For food processing facilities where daily washdown is part of normal operation, purpose-built washdown industrial PCs provide higher reliability, lower maintenance, and long-term peace of mind.